|

贵州六新洗煤有限公司 Guizhou Liu Xin Xi Mei Co. Ltd GKC Resources Pte Ltd |

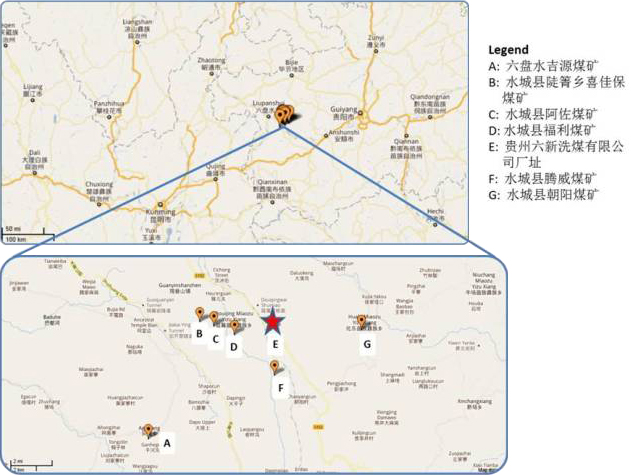

贵州六新洗煤有限公司 贵州六新洗煤有限公司Guizhou Liu Xin Xi Mei Co. Ltd Our plant is strategically situated at the junction of major highway and is less than 15km from the railway station. Currently, we have identified 6 potential coal mines for future acquisitions. Our close proximity to coal mines coupled with well-developed infrastructure provides GZLX with a steady supply of raw materials that enables us to deliver clean coal to our customers at competitive prices.  Given China's recent commitment to the environment and energy conservation, the Chinese Government has mandated the closure of small, inefficient and environmentally-unfriendly coal washing plants. This move has allowed larger, more modern coal washing plants like Guizhou Liuxin to have a distinct advantage in buying raw coal and supplying washed coal. Our plant utilises a high-tech coal washing process for coal washing to meet customers' stringent requirements. The process used is environmentally-friendly and energy-efficient. This initiative is in line with the Chinese government's policies to reduce environmental pollution and to conserve energy. Uses for Clean Coal Clean coal technologies are several generations of technological advances that have led to more efficient combustion of coal with reduced emissions of sulphur dioxide and nitrogen oxide. Production of Coke Coal often show wide divergence both in physical and chemical properties of coal. This leads to variation in density, hardness, sizing and cleaning characteristics, coking property, ash, volatile matter, sulphur and phosphorus content. The coal quality is enhanced by coal washing to reduce the ash, sulphur and phosphorus content. Coal Gasification Gasification is a process that avoids burning coal. Coal gasifiers convert coal into syngas via partial oxidation reactions with oxygen or with steam and oxygen under elevated pressures. Syngas is made of carbon monoxide and hydrogen. It is then cleaned and burned in place of coal to produce electricity. Coal gasification also creates useful by-products – fly ash for the cement industry, sulphur for fertiliser manufacture and for chemical applications, and slag for building materials and for roads. |